State-of-the-art manufacturing plants

Thanks to the exclusive and automated advanced European technology used in our plants, our high-capacity output is in line with international standards. Our plants use the following machines:

Conti-Press Line

Converts resin into nanoparticles for uniform resin application and blending with the fibre. It also improves the board’s internal bonding, thereby enhancing its strength improves the board’s internal bonding, thereby enhancing its strength

Steinemann CTS & Sanding Machine

Enhances the mechanical and physical properties of the board, i.e., bonding, strength, thickness, swelling and the smoothness of the board. This is an advanced optical fiber analyzer used to measure fiber dimension in all the 3 axis to maintain and improve our fiber quality.

GreCon Dieffensor

Tests the formaldehyde emission content of the board to ensure that it adheres to international standards

Dieffenbacker Conti-Press Line

Tests the mechanical property of the wood

Automated Lucci System

Enhances the mechanical and physical properties of the board, i.e., bonding, strength, thickness, swelling and the smoothness of the board. This is an advanced optical fiber analyzer used to measure fiber dimension in all the 3 axis to maintain and improve our fiber quality.

Fisher+Ruckle Processing System

Tests the formaldehyde emission content of the board to ensure that it adheres to international standards

Multi-fuel hybrid energy generation plant from Thermax (India)

Tests the mechanical property of the wood

World-class lab

Greenpanel has an NABL accredited testing laboratory with IMAL test equipment from Italy, in accordance to ISO-IEC 17025:2005, located in-house to test our raw materials and finished products.

IMAL Integrated Resin Dosing System

Converts resin into nanoparticles for uniform resin application and blending with the fibre. It also improves the board’s internal bonding, thereby enhancing its strength improves the board’s internal bonding, thereby enhancing its strength

Fibrecam Equipment

Enhances the mechanical and physical properties of the board, i.e., bonding, strength, thickness, swelling and the smoothness of the board. This is an advanced optical fiber analyzer used to measure fiber dimension in all the 3 axis to maintain and improve our fiber quality.

UV Spectro Photometer & Perforator

Tests the formaldehyde emission content of the board to ensure that it adheres to international standards

Universal Testing Machine (UTM)

Tests the mechanical property of the wood

Uttrakhand Plant

The MDF manufacturing facility in Pantnagar, Uttrakhand, is the first-of-its-kind in India that incorporates the latest European technologies .

Andhra Pradesh Plant

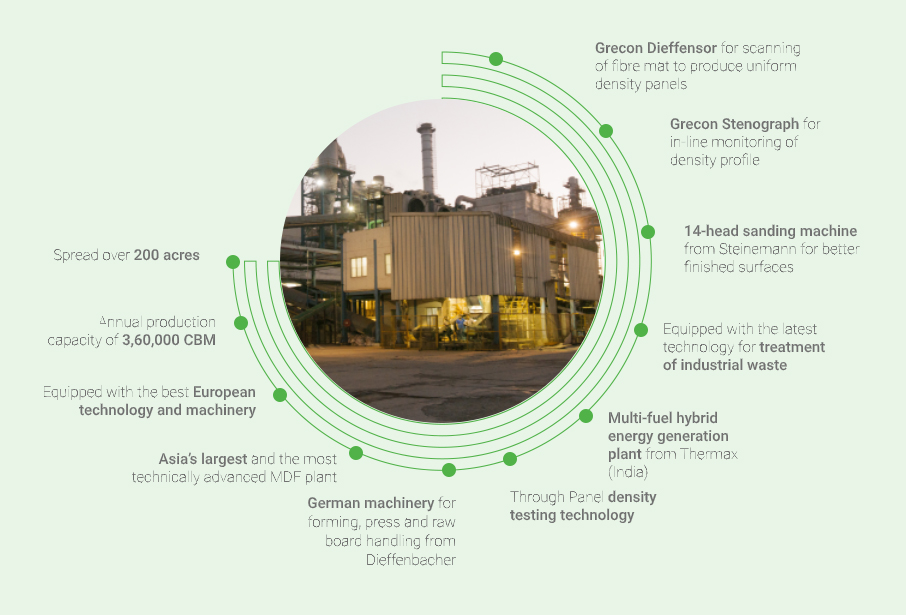

The new plant with an annual capacity of 3,60,000 CBM per annum is the largest MDF plant in Asia. The plant is equipped with advanced European machinery to give best quality products to our discerning customers. Quality control is an integral part of the production process with extensive quality testing measures put in place to ensure that the requirements of type and grade match the most stringent international standards. The plant is strategically located to ensure faster deliveries in South India.

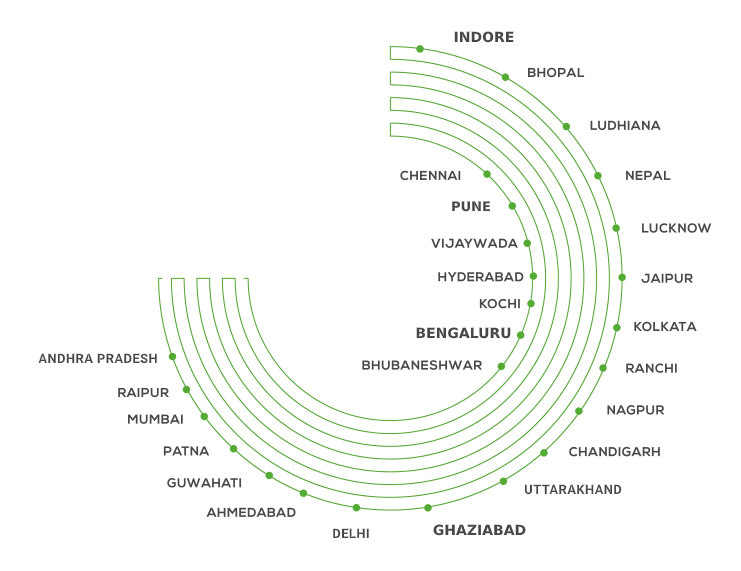

Robust sales and distribution

With a widespread network of 23 branches, two plants and more than 3000 retailers across the length and breadth of India, we cater to every need of our customers and give them service that is our forte. Be it new product information or customer support service, with such a robust network, you will find us just a call away.

-d.jpg)